Ten Reasons to Stitch and Whip Your Ropes

Ropes on cruising yachts are required to withstand the relentless wear and tear caused by working at sea. Stitching and whipping the end of a rope to bind all the separate strands, plaits and layers together in their designed configuration will guarantee the consistency of the rope construction. This article explains the importance of stitching and whipping.

Published 1 year ago

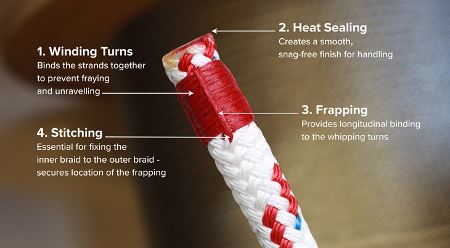

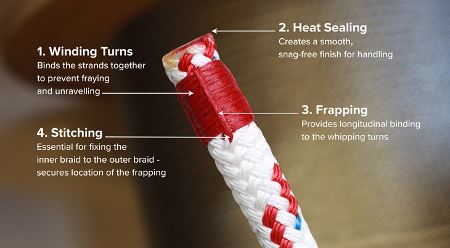

What is a Rope Whipping?

A rope whipping, also known as a whipping knot, is the process of binding a rope end to prevent it from fraying and unravelling. The technique can also be applied to bind two ropes together. This is commonly known as seizing.

The Stitching and Whipping technique is the most effective, long-lasting method of securing the end of a rope, whatever the application onboard, e.g. mooring, anchoring or rigging.

Ropes on cruising yachts are required to withstand the relentless wear and tear caused by working at sea. While abrasion is generally the enemy along the length of the line, the detrimental effects of flogging, flapping, banging, and bumping will take their toll on the ends, reducing their usable life and potentially causing injury through handling them.

To maximise the benefit, a whipping should also include a palm and needle stitching to fix all the strands or layers together, ensuring the integrity and consistency of the line construction.

There are four main rope whipping methods:

- Stitching and Whipping: also known as Palm and Needle Whipping.

- Common Whipping: started and finished with a common whipping knot.

- Westcountry Whipping: a series of thumb knots finished with a reef knot.

- Sailmaker’s Whipping: a combination of binding and frapping turns.

What is the best type of whipping for any rope?

The type or method of whipping to choose depends on the rope construction and the application. If you have the time and inclination, the stitching and whipping method is usually the best all-round method, as it is typically the most durable and effective version for most of the ropes you will encounter.

How long should a rope whipping be?

There is an old rule of thumb that says a whipping should be at least as long as the diameter of the rope. The more up-to-date recommendation for modern rope fibres and constructions is one and a quarter times the diameter. The extra winding turns make the whipping more secure and durable by spreading the tight grip over a larger area, and it will also make it seem more shipshape and seamanlike.

The upsides of stitching and whipping your ropes:

1. Weather and Wear Resistance

A good quality, waxed whipping twine is manufactured from UV and abrasion-resistant high-tenacity polyester, making it as durable as the rope itself. The wax additive acts as a lubricant that eases the progress of the twine through the strands, minimising the disruption of the fibres. In addition, the wax finish helps to create a tight and tidy winding by melding the twine wraps together into a close alignment as the tension is applied.

2. Cohesion of the Line Construction

Stitching and whipping the end of a rope binds all the separate strands, plaits and layers (inner and outer braids) together in their designed configuration, guaranteeing consistency of the rope construction.

Stitching is an essential part of the technique for a braided rope, e.g. Braid on Braid or Doublebraid, because it secures the outer jacket to the inner core, synchronising the tension in each constituent element to secure the correct balance throughout the length of the line.

Ultimately, if the two are not in equal tension, loops or bubbles of the inner braid will appear protruding from the outer braid. To have any chance of rescuing the situation, the two braids need to be realigned into a balanced tension before stitching.

3. Fraying and Unravelling Prevention

Whipping is simply the best, most durable method of safeguarding the end of a line from scruffy fraying and harmful unravelling.

4. Maximised Working Life of the Rope

The inner and outer braids will be subject to different tensions under load if they are not securely bound together at the ends. The ensuing imbalance of the forces through each separate braid will dislocate the designed structure of the fibres, seriously reducing working life expectancy. You can check for the first signs of this issue by running your hand along the rope feeling for any undulation. Any synchronicity problems will initially manifest as a slight unevenness, leading to rippling, wrinkling, and eventually loops of the inner braid appearing through the outer braid.

A Stitch and Whip is, therefore, the best method of protecting the rope from tension issues, thereby maximising the long-term effectiveness of any doublebraid line.

5. Colour Coding

It is normal practice to select a whipping twine colour to match the colour of the rope.

However, where there are several lines of the same colour, different colour whippings are extremely useful for quick identification.

A good example of this would be a set of six black dock lines of, say, three pairs of different lengths – each pair could have a different colour whipping on the end to identify their length – this could make all the difference in selecting the right warp first-time. The resulting rapid deployment at a critical docking moment might be just the action that saves embarrassment for all those involved.

6. Ropework Satisfaction

A trim, whipped finish to your ropes not only improves efficiency and longevity but also imparts a justifiable sense of pride in your handiwork, with an all-pervading feeling that all your mooring, anchoring and rigging lines are ready for the rigours of your next passage, or as the old seafarers would say: ‘Everything Shipshape and Bristol Fashion’.

Are there any good reasons for not stitching and whipping your ropes?

The one good reason is that the end of the rope may be terminated with a splice instead, although a whipping would normally be recommended to secure some splices.

What are the usual excuses for not stitching and whipping your ropes?

These normally boil down to time or cost. Stitching and Whipping is a time-consuming labour of love, demanding dexterity and practice. Therefore, patience and perseverance are the main recipe ingredients for achieving a smart, tidy, and effective result. This may explain why makeshift alternatives are so popular.

The repetitive aspects can also be physically demanding, requiring a firm grip, dexterity, and tough fingers. Practice, as they say, does make perfect, but attempting multiple whippings in one stint can lead to sore fingers and aching joints caused by continuously applying winding tension on the thin twine.

If a whipping is so important, why are unwhipped rope ends so prevalent?

You see so many ropes that are not properly stitched and whipped because there are several makeshift alternatives. These include heat sealing, DIY heat shrink, tape wrapping, a constrictor knot, a stopper knot, or any combination.

Why go to the trouble or expense of stitching and whipping your ropes if there are these alternative methods?

The reason is that although these expedient alternatives may appear to be doing the job all right at first glance, they don’t stand the test of time, and the problems increase when the ropes are working.

Therefore, rough and ready make-do alternatives will not prevent the problems from escalating every time you set sail, especially on long voyages. Therefore, these stopgap methods should only be viewed as temporary measures, not permanent solutions.

Let’s examine the temporary alternatives to whipping:

Heat Sealing

Sealing the end of a rope by melting the strands together with a heat gun or a lighter may look neat, but it will soon crack and fracture, leaving you back where you started. Heat sealing is an effective means of smoothing and rounding the end of a rope before applying a proper whipped finish.

Taping

Wrapping self-adhesive PVC (polyvinyl-chloride) tape around the end of a rope may work in the short term. Still, it has an unattractive appearance if applied untidily, and PVC does not weather as well as polyester rope. In addition, the tape will become brittle and lose its stickiness in the sun resulting in the tape failing to preserve the integrity of the rope end.

Heat Shrink

DIY heat shrink tubing is designed for bundling electrical cables but has been adapted for use on ropes. The Polyolefin is a step up from PVC but will not be as weather and abrasion resistant as the rope.

Heat Shrink is not self-adhesive, relying on the shrink ratio to sustain a successful tight fit. If you are planning to use heat shrink tubing, it is important to ensure that the wall thickness is up to the task because if it is too thin, it can lead to premature failure when the rope is working hard.

Knots

A constrictor knot applied with a thin cord or twine is a quick way to secure the ragged end of a rope, but it will not last as well as a whipping. A series of constrictor knots would be better, but it still leaves out the crucial stitch element.

A stopper knot will prevent the end of a rope from unravelling, but it will be rather clunky, getting caught just when you don’t want it to, and the end won’t run through any onboard system, e.g. sheaves, blocks, and fairleads.

Ten Top Reasons for Stitching and Whipping all your Rope Ends:

- Extends a rope’s effective working life

- Permanent, long lasting solution

- Toughest resistance to flapping and flogging

- Superior UV and weathering resistance

- Excellent resilience against wear and abrasion

- Renewable option at anchor, in port, or at sea

- Kind to crew hands

- Smooth, snag-free profile

- The Shipshape and Bristol Fashion effect

- Whipping is readily accessible to order with your ropes online

…………………………

About the Author

Jimmy Green Marine is a family-run business founded by brothers Alistair and Mike Green, based in the coastal fishing village of Beer in East Devon. The company started as a Mail Order Chandlers in 1981 and has continually evolved from attending Boat Shows and Boat Jumbles in the early days to now trading globally online.

Four decades of exporting experience combined with an intuitive website shipping calculator means that you can have your order delivered to your home, business or direct to your yacht anywhere worldwide.

Their flagship, innovative Custom Build website system provides an instant quote for all your professionally spliced and finished wire and rope rigging, mooring and anchoring solutions.

You can access this online from wherever you can get an internet connection, however remote.

Alistair Green is an experienced sailor and rigger with over 40 years of experience in the marine industry. He is passionate about providing his customers with the best possible products and services and is always looking for new ways to improve the business.

If you are looking for a reliable and experienced marine supplier, then Jimmy Green Marine is the perfect choice.

Visit their website today to learn more about their products and services.

…………………………

Related Links:

- About Jimmy Green Marine

- Custom Splicing, Rigging and Sewing Service

- Worldwide Shipping

- Jimmy Green Marine joins Noonsite.com as Official Ropes and Rigging Partner (April 2023)

Other Articles by Jimmy Green Marine:

- When to Replace your Standing Rigging (October 2023)

- How to Choose your Next Anchor Chain (August 2023)

- How to Choose a New Halyard (July 2023)

- The Uses and Benefits of Rope Splicing Onboard a Yacht (May 2023)

………………………………

The opinions expressed in this article are the author’s own and do not reflect the view of Noonsite.com or World Cruising Club.

………………………………

Find out all news, reports, links and comments posted on Noonsite, plus cruising information from around the world, by subscribing to our FREE monthly newsletter. Go to https://www.noonsite.com/newsletter/.

Related to the following Cruising Resources: Cruising Information, Equipment, General, Planning and Preparation, Repairs, Sails & Rigging