How to Choose Your Next Anchor Chain

Incidents of an anchor chain failing while a yacht is at anchor are extremely rare, but reports of yachts coming adrift from their anchor are becoming more frequent. So, when deciding on the best anchor chain for your yachting adventure, there are five big questions to be asked, as discussed in this article.

Published 1 year ago

When deciding the best anchor chain for your next yachting adventure, ask yourself five big questions:

- Do I want Hot Dip Galvanised or Stainless Steel?

- What Size Chain Do I Need?

- Which Chain Calibration will be best?

- How Long a Chain Will I Need?

- Which Chain Manufacturer Should I Choose?

The Pros and Cons of Galvanised Anchor Chain

Hot Dip Galvanising has been around for over five decades and is still the most popular finish for anchors and chains on motor and sailing yachts because it is much less expensive than stainless steel.

It is important to understand that Hot Dip Galvanising is not just a surface treatment like cold galvanising (also known as electroplating). This means that it isn’t just sprayed or painted on. Instead, when the chain is dipped in molten zinc, a chemical reaction infuses the zinc into the steel. Therefore, the bumps, scrapes and scratches that are a natural part of anchoring should only have a gradual effect.

The reality is that all galvanising will develop rust stains and eventually rust. As soon as you introduce your beautiful new galvanised chain into a marine environment, oxidisation and corrosion will begin. So, if you want a spotless blemish-free foredeck and chain locker, a high-grade stainless is the way to go for you.

The Pros and Cons of Stainless Anchor Chain

Stainless Steel Calibrated Anchor Chain is available from Grade 30, which is approximately three times the price of Galvanised Grade 40.

Staining can occur on stainless steel, despite what the name implies, but this can be removed with a specialist cleaning agent– this is very simple to use and does not require any drying or polishing.

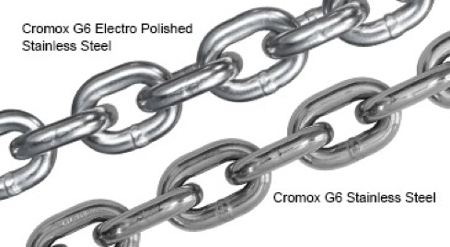

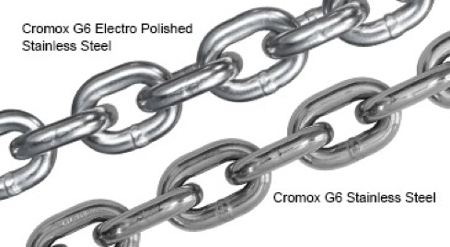

Stainless Grade 60 and Grade 60+ A318N Cromox chains manufactured by Ketten Waelder in Germany offer supreme quality, superior strength, and durability. An additional electro-polishing process is also available to deliver the ultimate resistance to marine degradation, highly recommended for warm oceans. They also argue that stainless steel is more eco-friendly because it will amortise the carbon footprint over a longer period and leave no zinc deposits in the ocean.

Mixing and Matching Galvanised with Stainless in your Anchor System

The two different steels are quite commonly seen together in an anchoring system. Still, you should know that this will cause a galvanic reaction between them, and it will be the galvanising that usually suffers accelerated corrosion. This is especially true if the mass of the stainless is much greater than the galvanised, e.g. a stainless steel anchor with a galvanised shackle and chain. The issue is less marked the other way around. For example, a stainless steel anchor connector is unlikely to adversely affect a large, galvanised anchor.

Ultimately, keeping to one steel throughout is best.

Stainless steel anchor connectors are frequently deployed between galvanised chain and anchor, seemingly, without any harm, but it will always be advisable to check each component regularly.

What Size Anchor Chain Should I Have?

Grades of anchor chain

The Grade of the steel is directly linked to the linear strength of each link and, therefore, the break load of the chain.

Grades are comparable between galvanised and stainless steel, although stainless is sometimes expressed with a simple G as a prefix rather than Grade, e.g. G3 equates to Grade 30

Galvanised anchor chain is generally available in Grade 30, Grade 40, and Grade 70. Although Grade 30 may suffice for coastal cruising, it doesn’t cost much more to upgrade to Grade 40, which delivers an extra 25% in strength.

Choosing Grade 70 means that you can step down a chain size, maintain or even increase the strength, and take advantage of the reduction in weight per metre by significantly increasing the scope.

A Stainless Steel anchor chain is generally available in G3, G4, G6 and G6+. As the denotation implies, stainless steel AISI 318LN G6+ is almost as strong as galvanised grade 70.

The weakest link

Incidents of an anchor chain failing while a yacht is at anchor are extremely rare, but reports of yachts coming adrift from their anchor are more frequent. This is because the integrity of your anchoring system is only as strong as the weakest link, so it is important to ensure that any splice, shackle or connector is at least as strong as the chain.

What are the main criteria for determining the right size anchor chain?

The chain size should be based on your chosen grade, yacht length, and displacement (windage may also be a factor).

However, your cruising expectations and how much you will rely on your anchor are equally important. One could argue that your anchoring system is your biggest insurance policy, so it is best to take it seriously.

Consider these two examples to give you an idea of the extremes. On the one hand, there you are, happily nipping out for the odd afternoon diddly, where you can duck back home at the slightest hint of bad weather. However, at the other end of the scale, you may be planning a round-the-world ocean voyage where you will depend on your anchor to hold in less-than-ideal anchorages and every conceivable weather.

Anchor chain size sources of information

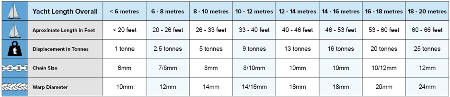

There are rules of thumb and plenty of size charts accessible online to determine the correct size for your yacht.

In Europe, Chain has simple metric sizing in 1mm or 2mm increments, e.g. 6mm, 7mm, 8mm, 10mm, 12mm, 13mm, 14mm.

Here is an example anchor chain and warp size guide in metric: (click on the image to see a bigger image)

Trying a few different sources is a good idea to see what other opinions there are and what they are based on, but you can get a good idea of what you will need from this chart – check the most appropriate column for your yacht and then overlay your anchoring reliance to make your decision.

An existing Windlass will shape your decision

The pulling power and the gypsy of your existing windlass may dictate your options.

The power affects how heavy an anchor and chain you can successfully retrieve, and the weight mainly depends on the anchor chain size and length.

There may be different gypsy options for the windlass, so it may be possible to change the size and calibration – Replacing one is relatively simple and inexpensive if it enables you to select the chain you think you need.

If you can’t or don’t wish to upgrade your windlass or change your gypsy, it will be the grade and the length of the chain that you need to focus on.

So, check your windlass first 😊

For information, in Europe, the chain wheel is commonly called a gypsy, but across the Atlantic, it is known as a wildcat.

Which Chain Calibration Do I Need?

Once you know the size of chain you want, you need to ensure you get the right calibration.

If you have a windlass, the short answer is the calibration that matches your gypsy, unless you are planning to upgrade your gypsy.

If you are buying a windlass, make sure the calibration of the chain and the windlass gypsy is a match.

There are two main calibrations of anchor chains in Europe: DIN766 and ISO4565.

Calibrated means that every link is guaranteed to be the same length and size within a certain tolerance.

How Long a Chain Will I Need?

The optimum chain length for your yacht will depend on how deep you expect your anchorages to be and your anticipated worst-case scenario anchoring conditions. You may be constrained by the depth and volume of your chain locker and by the maximum weight you feel happy to carry so far forward because it will inevitably affect your yacht’s performance.

There are traditional ‘rules of thumb’ for calculating length as a multiple of the anchorage depth. Although they aren’t very satisfactory for shallow or deep water, they make a good place to start.

Rules of thumb

The current popularly accepted ‘rule of thumb’ centres around a scope of 8:1 or even 10:1 for extended offshore and ocean cruising, which certainly seems reasonable for an anchoring depth of 10 metres, especially if that can be extended by, say, 20 metres of warp.

For coastal and occasional offshore cruising, 50 or 60 metres is more the accepted norm.

As windlasses have been developed with more retrieval capacity, the popular length for anchor chains has increased to a point where 80, 100 and even 120 metres are quite common, especially on larger yachts that can accommodate the weight in the bow.

If you are considering extending the length and weight of your current setup, check your windlass manufacturer’s recommendation on how much weight the motor is designed to pull at a safe working load. The windlass should have the power to pull up the full weight of the chain and anchor from very deep water, whether by accident or design. The constraints of the windlass retrieval capacity may render a rope extension your only option.

Combining chain with rope

An Anchor Rode can be all chain or a combination of rope and chain, in varying proportions.

These examples illustrate the range:

A short piece of chain of around 2-5 metres on the end of a long rope for those who still retrieve their main anchor by hand or for a light kedge or ‘lunch’ anchor.

An all-chain system on a windlass for ocean cruising where anchoring is of paramount importance – a short length of anchor rope spliced to the bitter end of the chain will provide a degree of shock absorption in severe weather as well as a neat method of attachment in the chain locker.

There is plenty of scope for options in between, especially where weight or space in the chain locker is limited.

This is another occasion for checking your windlass first. Your gypsy may be designed for just chain, or it may be a hybrid suitable for both rope and chain. If it is a combination rope/chain gypsy, remember to check the manufacturer’s suggested rope diameter and construction specification. Gypsy design has advanced, and recent models are much more forgiving, but older versions may be more restrictive. The manufacturer’s recommendation may not coincide with your idea of the ideal warp.

For example, you may believe you need a larger diameter or prefer an eight-strand Anchorplait construction rather than the traditional twisted lay rope. The upside is that there are plenty of gypsys out there working successfully with warps that go against the recommendations, and it is a relatively simple way to extend your rode without compromising the safe working load of your windlass. The potential downside is that you will need to sort yourself out if you have any compatibility issues.

How do I choose between Anchor Chain Manufacturers?

Buy the brand that you trust

Purchasing a recognised brand will assure you that the quality matches the marketing rhetoric.

Provenance makes the manufacturer accountable for their product. Traceability is also important. It is advisable to buy your chain from a creditable source with a system that records exactly which piece of a manufacturer’s chain you have been allocated.

Calibrated anchor chain for the European Marine Industry is generally manufactured in Europe or the Far East. There are no longer any calibrated anchor chain manufacturers in the UK, only distributors or former manufacturers who now only import their chains.

Yacht owners are justifiably wary of anchor chains manufactured in the Far East, but many globally renowned UK and European manufacturer brands manufacture under license worldwide.

Buy from a retailer that you trust

Consider the reputation, credibility, and integrity of the retail store as well as the manufacturer brand if you want to have confidence in your purchase. Buying from a dealer who specialises in anchoring rather than a general chandler could be the way to go.

Requesting a specific test certificate, not just a generic one, is prudent. The certificate should relate directly to the batch of chain from which your piece has been cut for complete peace of mind.

Where is anchor chain manufactured?

European chain is notably manufactured in France, Germany and Italy. China is the main alternative source.

The Rocna anchor is an example of a well-known quality product made in China where the brand and distribution network guarantee any necessary after-sales support.

The Titan brand is upheld by CMP (Canada Metal Pacific), who manufacture both Titan chain and the Rocna anchor in China.

If your preference is European, the MF CATENIFICIO factory in Italy is leading the way in innovation with a Solid Zinc duplex Hot Dip Galvanising process for both Grade 40 and DAMS Grade 70 anchor chains.

Please note that the chain and the windlass don’t need to be from the same manufacturer because it is the calibration that needs to match, but if you don’t have any other preference, it is a reasonable option.

Lofrans are world-renowned windlass manufacturers based in Italy who also produce chains under the Lofrans brand, although their chain is manufactured in China, just like Titan.

Corrosion Resistance

Galvanised chain

The galvanising quality will always be the main concern because nobody wants a rusty chain onboard. Manufacturers usually publish a minimum depth in microns, but producing a consistently good quality finish with 100% coverage to that depth is problematic because of the chain’s interconnecting nature and onerous weight. At least if you buy a trusted brand, any failure in performance should not fall on deaf ears.

Stainless steel chain

Staining and pitting are the enemy and directly related to the grade.

G3 is adequate for anchoring in temperate waters if you accept a degree of staining.

Ketten Waelder, based in Germany, produce Cromox, which is recognised worldwide as the finest brand for G6 and G6Plus stainless steel anchor chains.

Summary Checklist – 10 Important Steps to Buying an Anchor Chain

- Check your windlass for maximum retrieval capacity

- Check your windlass gypsy for size, calibration, suitability for rope as well as chain

- Decide whether to upgrade the gypsy

- Consider whether the origin matters to you, for example, the Far East, USA, Europe, Turkey

- Select Galvanised or Stainless Steel

- Decide on the size and grade (strength) you need

- Get the calibration right

- Pick a manufacturer brand that you believe in

- Buy from a trustworthy dealer

- Ask for a specific Test Certificate

…………………………

About the Author

Jimmy Green Marine is a family-run business founded by brothers Alistair and Mike Green, based in the coastal fishing village of Beer in East Devon. The company started as a Mail Order Chandlers in 1981 and has continually evolved from attending Boat Shows and Boat Jumbles in the early days to now trading globally online.

Four decades of exporting experience combined with an intuitive website shipping calculator means that you can have your order delivered to your home, business or direct to your yacht anywhere worldwide.

Their flagship, innovative Custom Build website system provides an instant quote for all your professionally spliced and finished wire and rope rigging, mooring and anchoring solutions.

You can access this online from wherever you can get an internet connection, however remote.

Alistair Green is an experienced sailor and rigger with over 40 years of experience in the marine industry. He is passionate about providing his customers with the best possible products and services and is always looking for new ways to improve the business.

If you are looking for a reliable and experienced marine supplier, then Jimmy Green Marine is the perfect choice.

Visit their website today to learn more about their products and services.

…………………………

Related Links:

- About Jimmy Green Marine

- Custom Splicing, Rigging and Sewing Service

- Worldwide Shipping

- Jimmy Green Marine joins Noonsite.com as Official Ropes and Rigging Partner (April 2023)

Other Articles by Jimmy Green Marine:

- When to Replace your Standing Rigging (October 2023)

- Ten Reasons to Stitch and Whip Your Ropes (September 2023)

- How to Choose a new Halyard (June 2023)

- All About Rope Splicing (May 2023)

………………………………

The opinions expressed in this article are the author’s own and do not reflect the view of Noonsite.com or World Cruising Club.

………………………………

Find out all news, reports, links and comments posted on Noonsite, plus cruising information from around the world, by subscribing to our FREE monthly newsletter. Go to https://www.noonsite.com/newsletter/.

Related to the following Cruising Resources: Equipment, General, General, Global Yachting Services

Thank you, this was a great, well articulated and very detailed article for an aspiring sailor. I gobble up tech info like this, hoping one day soon, it will be very useful for my life. One issue though, is that chart that is embedded about chain size and boat specs is illegible. I even tried copying it and pasting it into a word editing document as a scalable image so I could read it, and when I reached the maximum image width in a document oriented to landscape page orientation, I still could not read it. Can you or someone at Noonsite make it a clickable pop-up image with larger text? I feel like it’s a gold mine of a table of info, it’s just too bad I can’t read it easily. Otherwise, very great article, thank you! ~Debra

Hi Debra

If you click on the image of the table now, it will open up a larger version of the image which you should be able to download and refer to offline.

Hope this helps.